BMW M50 M52 M54 Six Cylinder Engines

M50 in an early E34 525i, later E34s had the battery under the rear seat.

Chronology

The story starts in 1983 when BMW pondered how to develop the M20 "little six". Various two and four valve options were investigated and a four valve prototype M22 was built. It was this engine that evolved into the M50. It used the same 91mm gap between cylinders as it's predecessor.

In 1989 the M50 replaced the M20 "little six" after ten years in service. The M50 was sold in the E34 520i, 525i and E36 320i, 325i whilst the M20 soldiered on in the E30 for a few more years.

In mid-93 the M50 became the M50TU with variable timing on the inlet camshaft. This gave the engine more mid-range torque but the same peak power. The M50 was regarded as a stronger engine by those who built race motors, but the TU proved just a reliable in normal use.

The M50TU replaced the old flap based Air Flow Meter (AFM) with a modern hot film Mass Air Flow (MAF) meter. This increased reliability on older engines where the AFM could often wear and cause running problems. It also reduced intake restriction and gave better air flow.

The M52 replaced the M50 in 1995 in 2.0, 2.5 and 2.8 capacities. After three years the M52TU entered the market, the main change was VANOS on both camshafts which is a handy recognition feature.

Last in this series was the M54 at the turn of the millenium which brought an increase in size to 2.2, 2.5 and 3.0 along with a raft of minor upgrades.

This whole series of engines is excellent and highly reliable. The M54 is a real peach.

Design

Compared to the earlier M20 the M50 was a very different beast. Not only did it have four valves per cylinder but the distributor was replaced by a one coil per cylinder design with the coil mounted directly above the spark plug. BMW's first venture into this technology on the M42 1.8 had a separate coil pack connected to the plugs by conventional HT leads. It was BMWs first engine with a serpentine belt instead of multiple fan belts. The M20's "spin on" oil filter was upgraded to an easy access canister design where only a new paper element was dropped in.

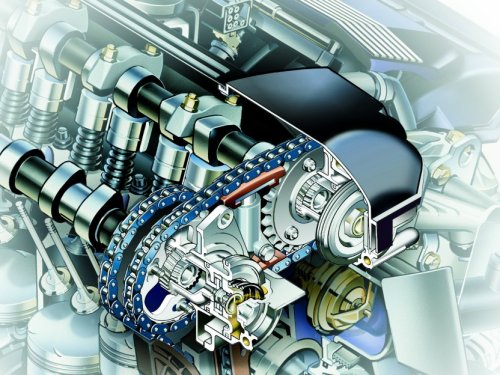

This was BMW's first engine to have a plastic intake manifold. For the M20 BMW's experimented with timing belts (along with the M40), thankfully the M50 went back to using a chain. In another departure the manually adjustable tappets on the M20 gave way to hydraulic tappets as used on the M42.

The camshafts were mounted in bearings which were split in half. On the older M20 and M30 "big six" removing the cam without taking the head off first was a nightmare. BMW fitted electronic knock detection as an input to the DME. All in all the new engines needed less maintenance and were easier to work on in most areas.

M52tu in the raw.

In addition to it's larger size option the M52 brought in an aluminium block which saved around 30kg, but not all was plain sailing. The Nikasil liners worked fine in Germany under testing, but in markets where fuel had a higher sulphur content they wore causing the bore to become oval. BMW replaced a lot of engines under warranty (also M60 V8s) before countries like the UK adopted low sulphur petrol. In the USA the M52 had a problem free steel block, although I'm not sure if this was for the whole production run. Confusingly the US Z3 used the euro aluminium block. The M52TU had different liners which fixed the problem.

In order to meet German insurance group limits the power on the 2.8 was limited to only 1bhp more than the M50B25. VW/Audi and Mercedes did something similar with their 2.8s. It made a lot of torque and was a quicker engine, but at the top end it wasn't what it should have been. The restriction was the inlet manifold which flowed a good deal less air than the M50s. It's not uncommon to fit an M50 manifold to an M52 and gain 30-40bhp, although a wee bit of plumbing and fettling is needed to make the ancillary hoses fit.

The 2.8 used a stronger forged crankshaft, the 2.5 and 2.0 used a cheaper cast item. The catalytic converters are mounted very close to the exhaust ports to make them heat up faster.

M52s with traction control actually had two throttles in series. The second throttle was used by the ASC+T system to reduce engine power when the wheels spun.

M52TU VANOS gear.

For the M52TU BMW introduced VANOS on both camshafts and changed from Nikasil to dry cast iron liners. The castings for both head and block were different with detail changes. The intake manifold used BMW's DISA technology to vary the length of the intake runners at different engine speeds and thus optimise torque. For this reason an M50 manifold conversion is more complicated. The oil filter canister was given a plastic instead of aluminium cover with a quite different design.

On the M52TU BMW introduced the dreaded Oil Separator Valve (OSV), dreaded because they fail although they seem to fail more on the M54. Doubtless needed to reduce emissions and meet tougher laws. On older engines fumes which passed up to the valve cover were just sucked back into the intake. Now they went into a separator to remove any oil and pass it back to the sump whilst the now clean air was reingested as before. But they can clog, especially if you do a lot of short journeys.

M54 in an E46 325i.

With the M54 we saw the six cylinder engines get their first mass production electronically controlled throttle, although my E34 Alpina B10 3.5 had this in 1989 because it had the optional traction control (using a throttle body from the M70 V12 which had a pair) it was never a factory option. The electronic throttle eliminated the double throttle system used on the M52TU with traction control.

The 3.0 unleashed the beast and power went up to 231bhp compared to 193 for the restricted M52 2.8. The 2.2 gave 170bhp, 20 more than the 2.0 it replaced. My E46 325i feels just as fast as my E36 328i and revs much better. The M54 is a glorious engine, for the 330i Club Sport they managed to find another few horses.

Early M54s used the traditional BMW viscous coupling and cooling fan. But as air conditioning became a standard feature BMW dropped this and used the a/c electric fan without the mechanical one. This made a small improvement to rotating mass.

An electronically controlled thermostat was fitted to the M54. On the very early cars it had a high failure rate, so high that many new cars were temporarily off the road due to a shortage of replacement thermostats.

Variants

| Code | Size | Power bhp@rpm |

Torque lb/ft@rpm |

BHP/ litre |

Torque/ litre |

Made | Bore x Stroke |

Timing | Weight (kg) |

VANOS | Used in |

| M50 / M50TU | 2.0

2.5 |

150 @ 5900

192 @ 5900 |

140 @ 4700

181 @ 4700 |

75

76.8 |

70

72.4 |

89 - 98

89 - 95 |

80x66

84x75 |

Chain | 136 | Single on TU |

320i,520i

325i, 525i |

| M52 / M52TU | 2.0

2.5 2.8 |

150 @ 5900

170 @ 5500 193 @ 5300 |

140 @ 4200

180 @ 3950 207 @ 3950 |

75

68 68.9 |

70

72 74 |

96 on

95 on 95 on |

80x66

84x75 84x84 |

Chain | 118 euro

140? USA |

Single

Double on TU |

E39 520i

E36 323i, E39 523i E36 328i, E39 528i, 728i |

| M54 | 2.2

2.5 3.0 |

170 @ 6100

192 @ 6000 231 @ 5900 |

155 @ 3500

181 @ 3500 221 @ 3500 |

77.3

76.8 77 |

70.5

72.4 73.7 |

autumn 2000

autumn 2000 early 2000 |

80x72 84x75 84x89.6 |

Chain | 126 | Double | '99 Z3, E39 and E46 |

Problems

The M50 is a very reliable engine. I've known two to snap chains at around 100k miles but this seems a rare fault. If it sounds rattly try a new tensioner piston, very cheap and easy to fit.

BMW engines in the 90s sometimes used water pumps with a plastic impeller, I suppose the idea was to eliminate rust. These plastic pumps can shatter and parts can end up all through the cooling system. It's often miss-diagnosed as a blown head gasket. Steel headed pumps are an easy cure.

On the M52 the aluminium block used in most cars can have worn bores due to sulphur damage. In practice this isn't going to be a problem on any car you look at today. Most countries now have low sulphur fuel and if an engine was going to fail it'd have done it by now.

Unlike the //M3 engines the VANOS on these cars is seldom a problem if they'd been looked after.

On the M54 the Crank Case Ventilation (CCV) / Oil Separator Valve (OSV) can fail. Symptoms are high oil consumption, poor running and sometimes a whistling noise. It's located under the throttle body and it's a 4-8 hour job to replace it. You need all the plastic tubing that feeds it and the line to the dipstick tube. You also need to remove and clean the dipstick tube then fit a new O ring. My 325i had this when I bought it, no doubt due to a lot of short drives on a cold engine. I bought the parts to fix it for 90 quid but after a few months of nothing but long drives and a lot of revs the thing cleared itself :-)

I've never stalled a car in traffic as much as my E46 325i, it's embarrassing. I thought it was just me but my mate says his E39 530i is the same. We think they just run very lean at idle and the idle speed is a bit low. It's worse when the engine is cold.

The O rings that seal the valve cover above the spark plug recesses can leak and let oil pool around the spark plugs. Easy to spot, just pull the HT lead and look for oil.

Ham fisted mechanics can easily over tighten the bolts that hold down the valve cover. This leads to oil leaks. You could use a heli-coil to re-thread the hole but or if it's at the front get a new upper timing case cover.

The M54's 15,000 mile service interval is a daft idea. It may appeal to tight fisted fleet managers and I'd agree the oil is capable of it. But the filters are toast before then. Personally I'd change it a bit sooner and replace the filter after 6000 miles because it's cheap and takes five minutes. It also relies on whoever changes the oil to use the right stuff which is a lot more expensive than normal oil. A back street garage looking to make a bit more profit might skimp and use cheaper stuff. If in doubt run an oil flush like Winn's then put in some decent oil.

If it miss-fires and need a new crankshaft position sensor pay up and get a genuine BMW one, after market ones can be problematic.

If an engine sounds very clattery it can be due to air in the hydraulic valve lifters. This can happen if the oil level falls very low or the car is used for nothing but very short trips, I've seen it once. The solution is to bleed the lifters. Warm the engine up with a short drive then with the car stationary run the engine at 3500rpm for three minutes, this can be tried several times back to back if needed. Certainly worked for me.